Rotary Heat Transfer Machine or Rotary Heat Press Sublimation Factory For Curved heat transfers or Cups or Plates

Datos del producto:

| Lugar de origen: | China |

| Nombre de la marca: | Osmanuv |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-ZY- 1320T |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 sistema |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Caja de madera |

| Tiempo de entrega: | 30 DÍAS DEL TRABAJO |

| Condiciones de pago: | T/T, Western Union |

|

Información detallada |

|||

| Nombre de producto: | Equipo termal de la transferencia | Tamaño: | 3000 milímetros x 2300 milímetros x 2100m m |

|---|---|---|---|

| Color: | Ordenador blanco/verde | Velocidad: | 1-3 m/min |

| Voltaje de fuente: | 380V 50HZ | Altura de funcionamiento: | 850m m (altura de la tierra), altura de la correa del rodillo con la exhibición de la posición |

| Resaltar: | Máquina rotativa de transferencia de calor para tazas,Prensa rotativa de calor para sublimación,Máquina de transferencia de calor curva para platos |

||

Descripción de producto

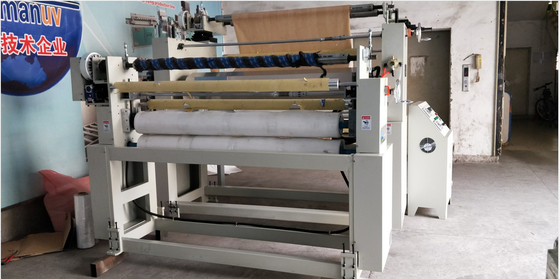

3m/Min 380V Rotary Heat Press Sublimation / Roll To Roll Heat Press

Thermal transfer is also called sublimation, which is to print any pictures such as portraits and landscapes on plain paper or high-precision printing paper with thermal transfer ink, and then heat it up within a few minutes by the corresponding thermal transfer equipment. At a certain temperature, the color of the image on the paper is realistically transferred to the porcelain cup, porcelain plate, porcelain plate, clothes, metal and other materials.

Description:

suitable for all kinds of wood, plastics, ceramics, calcium silicate board, metal and other plane overlay a layer of heat transfer film, so that the plate surface pattern level more clear, more three-dimensional sense.

Describe

| 1 | Mechanical dimension: |

3000mm long * 2300mm wide * 2100mm high. (Subject to the actual size). |

| 2 | Effective working size |

a. Effective width: 1300mm; b: Thickness: 1-60mmc, Length (shortest) : 600mm. |

| 3 | Supply voltage | 380V 50HZ. |

| 4 | Material |

The shell is made of 1.5mm cold-rolled plate bending and welding, the surface is treated with liquid paint, the frame is made of 100*50mm channel steel, and the supporting wall is made of 20cm steel plate (A3 material). |

| 5 | Fitting part: |

the double roll extrusion at the same time, so that the transfer film evenly bonded to the substrate, and through automatic entanglement device to prevent the film wrinkle. |

| 6 | Silica gel press roller | diameter: ¢210mm, length: 1400mm, high quality high temperature resistant silica gel made of Japan, wear-resisting, good elasticity, hardness can be customized according to customer requirements (30 degrees -- 50 degrees) between, can be resistant to all kinds of solvent with high quality coupling transmission, bearing using Japanese NSK bearing, Taiwan Bay Delphi frequency converter control cots speed. |

| 7 | Conveying mode | Adopt cots to transfer, smooth conveying and long service life. |

| 8 | Transportation speed |

1 ~ 3 meters/min. |

| 9 | Working height: | 850mm (belt height from ground), roller height equipped with position display. |

| 10 | Electrical appliances |

OMRON relay, Siemens motor, Delta frequency converter, reducer, CHNT contactor, delay using CKC brand, switch using Japan Wazumi company production, all in line with CE standard. |

| 11 | Safety device |

The machine has leakage circuit breaker, motor overload protection, abnormal emergency switch, control line fuse and other compliance with international safety standards. |

FAQ

Q: Are you trading company or manufacturer?

A: We are a manufacturer owns foreign trade independent import and export rights. Our factory is located in Guangdong, China.

Q: How can I know your machine has good quality?

A: Firstly, we will have your samples for a trial on our machines, and make a video for you to watch the testing, factory visit is also available. Moreover, our products are widely used in China, Southeast Asia, South America, and Europe.

Q: What certifications do you have?

A: Fully in accordance with the GMP & ISO standard production and our products have passed CE certification for exporting.

Q: What is your Quality Warranty?

A: One year warranty; Lifelong Maintenance and Technical Support.

![]()

![]()