Automatic Wood Panel Spray Coating Line for Furniture Board Painting: High-Efficiency Finish Spraying Machine for MDF

Datos del producto:

| Lugar de origen: | China. |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-PT-1320 |

| Documento: | automatic spray coating mac...ne.pdf |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 set |

|---|---|

| Precio: | negotiable |

| Detalles de empaquetado: | Envasado de madera |

| Tiempo de entrega: | 40 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| Nombre del producto: | línea de producción de recubrimiento en aerosol | La transmisión es limitada de ancho: | 1320m m |

|---|---|---|---|

| Velocidad de la línea de producción: | 1-15m/min | capacidad de clase única: | 1 pieza/min |

| Energía eléctrica: | 157kw | Nivel de maniormente: | 3-5 personas |

| Resaltar: | automatic wood panel spray coating line,furniture board painting machine,MDF spray coating machine with warranty |

||

Descripción de producto

Automatic Wood Panel Spray Coating Line for Furniture Board Painting: High-Efficiency Finish Spraying Machine for MDF

-

Composition of Production Line:

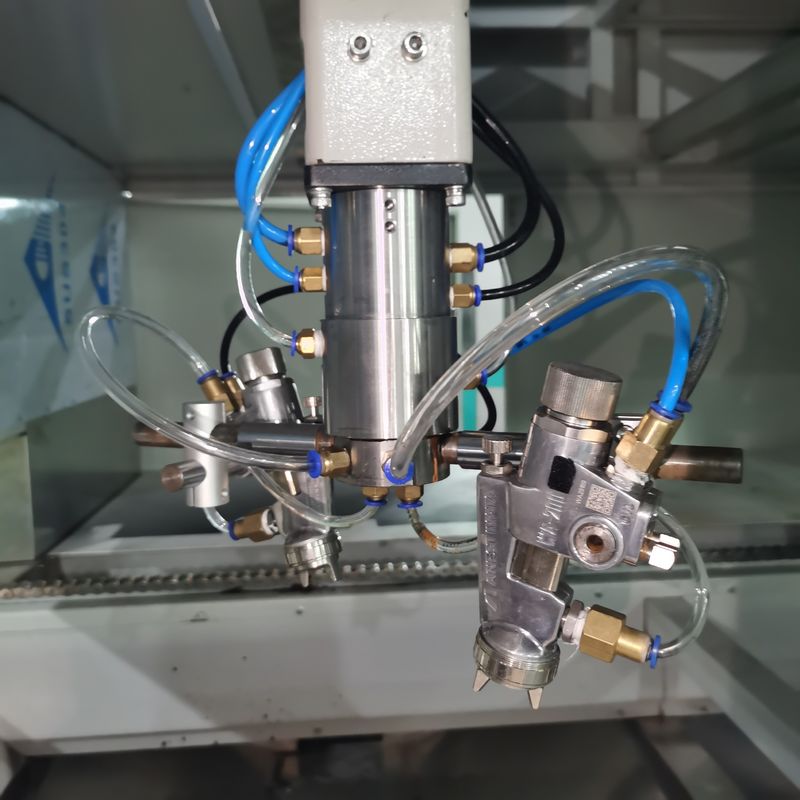

This integrated system comprises an automatic loading unit, precision dust removal station, automatic air spray guns (or robotic arms), manual touch-up station, drying tunnel (IR or Hot Air), cooling section, and automatic unloading & stacking unit. -

Product Description:

Our automatic spray coating line is designed for furniture panel manufacturers seeking a perfect balance between high efficiency and exceptional finish quality. It utilizes automatic spraying technology to achieve uniform coverage on complex surfaces and profiles, significantly reducing paint consumption and labor costs compared to manual spraying. Ideal for medium to high-volume production of cabinet doors, furniture parts, and decorative panels. -

Technical Parameters:

| Parameter Category | Details & Specifications |

|---|---|

|

Specifications |

4200mm long * 3050mm deep * 2500mm high (subject to actual size) |

| Suitable Substrate | MDF, Particle Board, Solid Wood, Plywood |

| Max. Panel Width | 2500 mm (Customizable) |

| Max. Panel Length | 4200 mm (Customizable) |

| Line Speed | 3-15 m/min (adjustable) |

| Spraying Technology | Automatic Air Spray Guns with HVLP (Customizable to airless) |

| Number of Guns | 4-8 Units (Standard, Customizable) |

| Drying Method | IR Heater or Hot Air Oven (Customizable) |

| Control System | PLC + HMI Touch Screen |

-

Application:

Cabinet doors, furniture components, door skins, panel furniture with raised panel designs. -

Customization:

This line can be customized with robotic arms for 3D components, additional gun stations for dual-color coating, or specific drying systems to match your paint chemistry. -

Feature:

-

High Transfer Efficiency (HVLP) reducing paint waste.

-

Consistent Finish on complex geometries.

-

Semi-Automated Operation with manual touch-up station.

-

Paint Circulation System for continuous operation.

-

-

Support and Services:

On-site installation guidance, comprehensive operator training on spray gun maintenance and operation, and 24/7 remote technical support. -

Packing and Shipping:

All major modules are disassembled and securely packed in weatherproof wooden crates. All parts are clearly marked for easy reassembly. -

FAQ:

Q: What is the paint utilization rate of this automatic line?

A: With HVLP (High Volume Low Pressure) spray technology, the transfer efficiency can reach up to 75-80%, significantly higher than traditional air spray, reducing paint waste and overspray.