Línea de recubrimiento de transferencia de LED UV compacta para acabados ecológicos en paneles compuestos de madera

Datos del producto:

| Lugar de origen: | PORCELANA |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-UVzy-1320 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 set |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Envasado de madera |

| Tiempo de entrega: | 35 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| Tipo de secado: | Secado IR | Velocidad de alimentación: | 1-20m/min |

|---|---|---|---|

| Tamaño: | 16800 × 1700 × 1940 mm | Qty del rodillo: | 2 pcs |

| Espesor de procesamiento: | 3-80m m | Cuota de la cabeza: | dos/tres/cuatro |

| Diámetro de goma: | 100 mm | Poder de trabajo: | 251 kW |

| Resaltar: | línea de recubrimiento UV LED compacta,Máquina de revestimiento UV para paneles de madera,revestimiento de transferencia UV respetuoso con el medio ambiente |

||

Descripción de producto

Línea compacta de recubrimiento por transferencia UV LED para acabados ecológicos en paneles de compuestos de madera

Descripción del producto

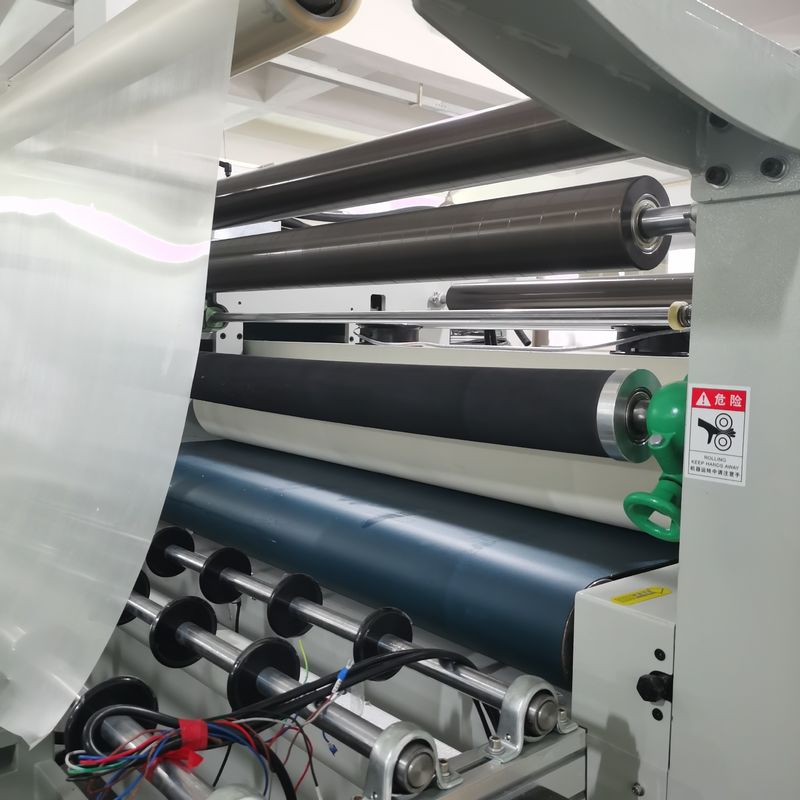

Esta línea compacta de recubrimiento por transferencia UV LED está diseñada para pequeñas y medianas empresas que buscan una solución de acabado ecológica y eficiente en el espacio. Utilizando curado UV LED de baja temperatura y eficiencia energética, aplica recubrimientos duraderos y de bajo VOC en paneles de compuestos de madera como MDF y aglomerado. Con una huella mínima y capacidades de cambio rápido de trabajo, es perfecta para tiradas cortas y pedidos personalizados sin comprometer la calidad del acabado ni la velocidad de producción. La configuración del sistema es altamente personalizable para varios tamaños de panel y tipos de recubrimiento.

Parámetros técnicos

| Parámetro | Especificación |

|---|---|

| Modelo | OSM-UVZY-1320 |

| Sustrato de aplicación | MDF, Aglomerado, Compuestos de madera |

| Ancho máximo del panel | 1320 mm estándar (Personalizable) |

| Velocidad de la línea | 4-20 metros/min |

| Sistema de curado UV | 1 x 3000mJ/cm² Unidad LED UV (Baja emisión de calor) |

| Fuente de alimentación | 220V / 50Hz o 380V / 50Hz (Personalizable) |

| Potencia total | 25 kW (aprox.) |

| Huella | Diseño compacto, ~12m de longitud |

| Sistema de control | PLC fácil de usar con recetas preestablecidas |

Aplicación

-

Ideal para talleres y fabricantes de muebles a medida que producen tiradas cortas a medianas de paneles acabados.

-

Aplicación de recubrimientos ecológicos y de bajo olor para muebles de interior, mobiliario de oficina y accesorios de tiendas.

-

Una solución versátil para la creación de prototipos de nuevos diseños y acabados.

Característica

-

Tecnología UV LED: Curado de encendido/apagado instantáneo y eficiente energéticamente sin tiempo de calentamiento y mínima emisión de calor.

-

Huella compacta: Diseñado para caber en espacios de producción más pequeños sin sacrificar la capacidad.

-

Ecológico: Compatible con recubrimientos UV 100% sólidos y de bajo VOC para un proceso de fabricación más ecológico.

-

Cambio rápido: La configuración fácil de ajustar permite transiciones rápidas entre diferentes trabajos y acabados.

Personalización

Esta línea está construida para ser personalizada:

-

Voltaje y potencia: Configurado para el suministro eléctrico de su taller local.

-

Ancho y longitud: Adaptado a los tamaños de panel más comunes y al espacio disponible.

-

Nivel de automatización: Opciones desde carga manual hasta funcionamiento semiautomático.

Soporte y servicios

Proporcionamos videos instructivos detallados, sesiones de capacitación en línea y acceso directo al soporte técnico para obtener asesoramiento sobre solución de problemas y mantenimiento.

Embalaje y envío

La línea compacta a menudo se envía como una sola unidad preensamblada sobre un patín para facilitar la descarga y la configuración rápida en sus instalaciones.

Preguntas frecuentes

-

P: ¿Cuáles son los beneficios de los costos operativos de UV LED?

-

R: Los LED UV consumen menos energía, tienen una vida útil más larga (más de 20.000 horas) y no producen calor, lo que reduce los costos de refrigeración, lo que genera importantes ahorros a largo plazo.

-

-

P: ¿Es esta línea adecuada para una fábrica sin experiencia previa en UV?

-

R: Absolutamente. Sus controles fáciles de usar y nuestra capacitación integral la hacen accesible para los operadores nuevos en la tecnología UV.

-