Máquina de secado por microondas industrial para moldeo de celulosa - Sistema de túnel personalizable para bandejas de huevos y envases de alimentos

Datos del producto:

| Lugar de origen: | Porcelana |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | Se aplican las siguientes medidas: |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 juego |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Caja de madera |

| Tiempo de entrega: | 30 a 45 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| La forma seca: | Microonda | Alimentación de potencia: | 0.75kw |

|---|---|---|---|

| Velocidad de producción: | 15-25m/min | Dirección de marcha: | De izquierda a derecha |

| Marca de la frecuencia: | Shilin o Schneider | Tipo de placa: | Placa de gravedad |

| Error de plegado al rebobinar: | ± 0.1 mm | Transportación de la dirección: | De izquierda a derecha |

| Resaltar: | Máquina de secado industrial de microondas para moldeo de celulosa,sistema de túnel de microondas personalizable para bandejas de huevos,equipos de secado al vacío de microondas para envases de alimentos |

||

Descripción de producto

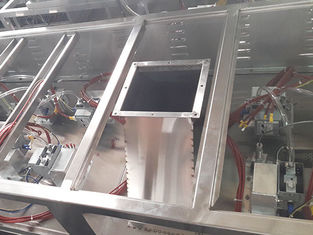

Máquina de secado industrial por microondas para moldeo de pulpa - Sistema de túnel personalizable para hueveras y embalaje de alimentos

Descripción del producto:

Esta máquina de secado por microondas de grado industrial está diseñada específicamente para la industria del moldeo de pulpa. Ofrece un secado rápido, uniforme y energéticamente eficiente para productos como hueveras, bandejas de frutas y embalajes de alimentos desechables. Al calentar directamente las moléculas de agua, reduce drásticamente el tiempo de secado de horas a minutos, lo que resulta en un producto final más fuerte y de mayor calidad con menor consumo de energía. Toda la línea de producción es personalizables para que coincida con su producción y la disposición de la fábrica.

Composición de la línea de producción:

-

Transportador de entrada (Sincronizado con la máquina de moldeo)

-

Cámara de calentamiento por microondas (Con matrices de magnetrones)

-

Sistema de circulación de aire caliente (Para la evacuación de la humedad)

-

Sistema de escape y deshumidificación

-

Transportador de salida y enfriamiento

-

Armario de control PLC con interfaz hombre-máquina (HMI) con pantalla táctil

-

Variador de frecuencia (VFD) para el control de la velocidad del transportador

Parámetros técnicos:

| Parámetro | Detalles |

|---|---|

| Modelo | Serie MWT-PM (Totalmente personalizable) |

| Potencia de salida | 30kW, 50kW, 80kW, 100kW (Seleccionable & personalizable) |

| Voltaje de entrada | 380V/415V 50Hz/60Hz 3 fases (o según Personalizado) |

| Rango de temperatura de secado | 70°C - 120°C (Ajustable con precisión) |

| Ancho de la cinta transportadora | 600mm, 800mm, 1000mm (personalizable) |

| Tiempo de secado | 5 - 15 minutos (Ajustable a través del VFD) |

| Sistema de control | PLC + HMI con pantalla táctil (Recetas programables) |

| Dimensión general | Personalizado según la potencia y la configuración |

Aplicación:

Industria del moldeo de pulpa para el secado de hueveras, bandejas de frutas, embalajes industriales, plántulas en macetas de papel y otros productos de fibra moldeada en 3D.

Personalización:

Ofrecemos una amplia personalización que incluye la longitud del túnel, el tipo y ancho de la cinta, la configuración de la potencia, la integración del sistema de control y la disposición general para que se adapte perfectamente a su línea de producción existente.

Características:

-

Calentamiento rápido y uniforme de adentro hacia afuera.

-

Hasta un 40% de ahorro de energía en comparación con los hornos convencionales.

-

Potencia y velocidad del transportador totalmente personalizables para diferentes productos.

-

Mejora la resistencia del producto y reduce la rotura.

-

Diseño compacto, que ahorra valioso espacio en el suelo de la fábrica.

-

El control PLC garantiza resultados consistentes y repetibles.

Soporte y servicios:

Brindamos soporte integral que incluye supervisión de la instalación, capacitación de operadores, asistencia técnica remota y un suministro de repuestos fácilmente disponible.

Embalaje y envío:

La máquina se embala de forma segura en una caja de madera apta para la exportación o en un marco de hierro para el transporte marítimo y terrestre seguro. Todas las piezas están claramente marcadas para facilitar la identificación.

Preguntas frecuentes:

-

P: ¿Puede esta máquina conectarse a mi máquina de moldeo de pulpa automática?

R: Sí, las alturas y velocidades de entrada y salida son totalmente personalizables para una integración perfecta. -

P: ¿El secado por microondas dañará la frágil estructura de la pulpa?

R: No, la temperatura y la potencia se controlan con precisión para evitar quemaduras o deformaciones, lo que resulta en un producto más consistente. -

P: ¿Cuál es el plazo de entrega típico?

R: El plazo de entrega depende del nivel de personalización, que suele oscilar entre 20 y 35 días laborables.