Túnel de secado por infrarrojos de alta velocidad para revestimientos a base de agua - Curado rápido e integración de procesos

Datos del producto:

| Lugar de origen: | Porcelana |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-UV-1320T |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 juego |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Caja de madera |

| Tiempo de entrega: | 30 a 45 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| Tipo de rodillo: | Alambre de acero | Velocidad de secado: | Secado rápido en minutos |

|---|---|---|---|

| velocidad: | ajustable | Requisito de mantenimiento: | Bajo mantenimiento con piezas de fácil acceso. |

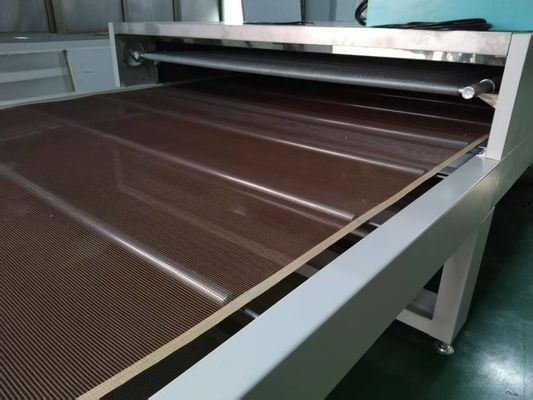

| PowerSource: | Electricidad | transportador de color: | Cinturón transportador de teflón |

| Tipo de instalación: | Independiente o integrado en la línea de producción | Garantía: | 1 año |

| Resaltar: | túnel de secado infrarrojo de alta velocidad,máquinas de secado por infrarrojos para revestimientos,secador de recubrimientos a base de agua de curado rápido |

||

Descripción de producto

Túnel de secado por infrarrojos de alta velocidad para revestimientos a base de agua - Curado rápido e integración de procesos

Composición de la línea de producción

Este sistema es un túnel de secado de infrarrojos modular diseñado para la integración en línea. Incluye un marco de acero inoxidable, emisores de infrarrojos de onda media de alta intensidad, una cámara altamente reflectante,un sistema de control de temperatura de varias zonas, y un gabinete de control integrado.

Descripción del producto

Este túnel de secado por infrarrojos de alta velocidad está diseñado para curar rápida y eficientemente los recubrimientos a base de agua en sustratos planos o simples.Transfiere energía directamente al revestimiento y a las moléculas de agua, reduciendo significativamente el tiempo de secado en comparación con los métodos convencionales de aire caliente, lo que conduce a un mayor rendimiento de producción y un acabado superior.

Parámetros técnicos

| Parámetro | Especificación |

|---|---|

| Modelo | Serie IRD-WB-HS |

| Tecnología de calefacción | Emitentes infrarrojos de onda media |

| Duración estándar | 2m, 3m, 5m (Personalizable) |

| Potencia de calefacción | 30-120 kW (Personalizable) |

| Rango espectral | 2.0 - 3,5 μm |

| Sistema de control | PLC con HMI y control de zona |

| Temperatura máxima de la superficie | Hasta 250 °C (ajustable) |

| Ancho del cinturón | Personalizablea su transportador |

Aplicación

Ideal para líneas de producción aceleradas:

-

Secado de revestimientos en paneles y componentes metálicos.

-

Curando pinturas en muebles, MDF y madera de ingeniería.

-

Pre-secado y curado final de perfiles de PVC y piezas de plástico.

Personalización

Este túnel infrarrojo es muyPersonalizablePodemos ajustar la longitud, la densidad de potencia y el número de zonas de control independientes para crear el perfil de temperatura perfecto para su química de recubrimiento específica y la velocidad de la línea.

Características

-

Seca rápida:Reduce el tiempo de curado de minutos a segundos, aumentando la velocidad de la línea.

-

Transferencia directa de energía:Muy eficiente, ya que la energía IR es absorbida directamente por el revestimiento, no por el aire.

-

Calentamiento uniforme:Diseño de emisores y reflectores para evitar puntos calientes.

-

Diseño compacto:Ahorra un valioso espacio en el suelo en comparación con los hornos de convección largos.

-

Encendiendo/apagando instantáneamente:No hay tiempo de calentamiento o enfriamiento, ahorrando energía.

Apoyo y servicios

Proporcionamos apoyo de integración, capacitación de operadores y una lista completa de piezas de repuesto.

Embalaje y envío

El túnel se envía como un módulo pre cableado, montado de forma segura en una caja de madera robusta para un transporte seguro.

Preguntas frecuentes

-

P: ¿Cómo se compara el secado IR con el aire caliente para revestimientos a base de agua?

-

R: IR es mucho más rápido y eficiente ya que calienta el recubrimiento y el agua directamente, lo que conduce a la evaporación y curado inmediatos, a diferencia de calentar el aire circundante.

-

-

P: ¿Se puede controlar la temperatura en diferentes secciones?

-

R: Sí, el secador tiene característicasPersonalizablezonación, permitiendo un perfil adaptado (por ejemplo, curado final agresivo y suave).

-

-

P: ¿Es adecuado para nuestro transportador de 800 mm de ancho existente?

-

R: Absolutamente. El ancho interno es completamentePersonalizablepara encajar en tu línea.

-