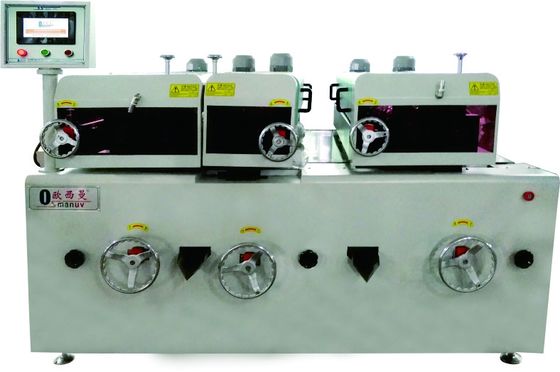

Línea de producción automática de revestimiento de múltiples rodillos para láminas metálicas y paneles de PVC

Datos del producto:

| Lugar de origen: | Porcelana |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-GT-1320 |

| Documento: | Two-roller coating machine.pdf |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 JUEGO |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Caja de madera |

| Tiempo de entrega: | 30 a 45 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | negociación |

|

Información detallada |

|||

| Durabilidad del recubrimiento: | Alta durabilidad | Dispositivo giratorio: | usando la rotación 90º eléctrica |

|---|---|---|---|

| Machine Name: | Brusher machine | La forma seca: | lámpara ultravioleta |

| Camino de enfriamiento: | Refrigeración por aire | Dimensión: | como requisito del cliente |

| Tipo de rodillo: | Alambre de acero | tipo de lámpara: | Tipo de fibra de carbono |

| Resaltar: | Línea automática de recubrimiento de chapa metálica,Equipo de recubrimiento con rodillos para paneles de PVC,Máquina de producción de recubrimiento multicilíndrico |

||

Descripción de producto

Línea de producción automática de revestimiento de múltiples rodillos para láminas metálicas y paneles de PVC

1Composición de la línea de producción

Este sistema completo incluye: alimentador automático de láminas, estación de limpieza/desbordaje de precisión, secador de pre-revestimiento de múltiples etapas,PersonalizableUnidad de recubrimiento de 2 / 3 / 4 rollos, túnel de apagado, horno de curado de alta eficiencia (termal o UV), sección de enfriamiento rápido, apilador automático con entremezcla de protección.

2Descripción del producto

Nuestra línea de recubrimiento industrial está diseñada paraaplicaciones de gran volumen y precisiónEl corazón del sistema es su capacidad de almacenamiento de materiales y materiales para la fabricación de pinturas, primeras y recubrimientos funcionales sobre sustratos rígidos como el metal y el PVC.totalmente personalizableConfiguración de rodillos, que permite un control exacto sobre el peso del revestimiento, el acabado y el ahorro de materiales.y aplicaciones industriales.

3. Parámetros técnicos

| Categoría de parámetros | Especificación | Las notas |

|---|---|---|

| Ancho máximo del sustrato | 1250 mm, 1500 mm, 1850 mm, 2200 mm. No hay más que un par de milímetros. | Tamaños estándar;anchos personalizadosDisponible |

| espesor del sustrato | 0.3 mm - 8.0 mm | Las demás máquinas y aparatos, de metal o de acero |

| Velocidad de la línea | 5 - 70 metros/minuto | Control de transmisión de frecuencia variable |

| espesor del revestimiento (película seca) | 10 - 250 micrones | Precisión controlada por el hueco del rodillo y la viscosidad |

| Rango de viscosidad del revestimiento | 50 - 5.000 cPs | Compatibles con revestimientos a base de disolventes y agua |

| Configuración del rodillo | El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de efecto invernadero. | Personalizablea las necesidades de la aplicación |

| Sistema de control | PLC industrial con pantalla táctil HMI de 10 pulgadas | Almacenamiento de recetas y registro de datos de producción |

| Requisitos de energía | 380V / 50Hz / de 3 fases (Estándar) | Configurable para otras normas regionales |

4Aplicación

Ideal para el revestimiento:Los paneles compuestos de aluminio (ACP), láminas de acero galvanizadas,Tablas de espuma de PVC, bobinas metálicas prefabricadas para techos y revestimientos, placas de MDF y otros paneles compuestos.

5. Personalización

Esto es unmuy personalizableLos principales aspectos personalizables incluyen:

-

Capacidad de producción:Velocidad de la línea y longitud del secador adaptados a sus objetivos de producción.

-

Proceso de recubrimiento:Elección de la configuración de los rodillos (2, 3 o 4 rollos) para diferentes efectos de acabado.

-

Manipulación del sustrato:Configurados para hojas o bobinas.

-

Seca y curado: Personalizadomódulos de curado por convección térmica, IR o UV.

-

IntegraciónDiseñado para encajar en el diseño de su fábrica existente y el equipo aguas arriba y abajo.

6. Características

-

Medidas de precisión:Garantiza un peso de revestimiento constante, reduciendo los residuos de pintura hasta en un 15%.

-

Los demás:Diseño modular para el cambio y la limpieza rápidos de rodillos (< 30 minutos).

-

Secado eficiente desde el punto de vista energéticoSistema de circulación de aire caliente con recuperación de calor.

-

Construcción robusta:Cuadro y componentes de acero inoxidable soldados de uso pesado en zonas húmedas.

7Apoyo y servicios

-

Preventa:Análisis de aplicaciones y planificación de diseño gratuitos.

-

Después de las ventas:Supervisión de la instalación en el sitio, entrenamiento integral del operador, garantía de 12 meses.

-

A largo plazo:Soporte de diagnóstico remoto, planes de mantenimiento preventivo, suministro garantizado de repuestos.

8Embalaje y envío

Todas las unidades principales son desmontadas, protegidas contra la corrosión y empacadas enCajas de madera resistentes a las intemperiePara el transporte marítimo, la carga en contenedores completos (FCL) es estándar.

9. Preguntas frecuentes

-

P: ¿Cuál es el tiempo de entrega para una línea personalizada?

R: El tiempo de entrega típico es de 90 a 120 días después de la confirmación final del diseño, dependiendo del nivel dePersonalización. -

P: ¿Puede proporcionar muestras recubiertas en su máquina?

R: Sí, podemos realizar pruebas de recubrimiento en nuestro centro de demostración con su sustrato y material de recubrimiento. -

P: ¿Ofrece un sistema de control en diferentes idiomas?

R: Sí, la interfaz HMI puede serpersonalizadopara incluir varios idiomas como inglés, español, alemán, etc.