High-Temperature Gas-Fired Drying Machine for Wood Panel Coating Heating

Datos del producto:

| Lugar de origen: | PORCELANA |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | OSM-TRQ-920 |

| Documento: | Natural Gas Drying Machine.pdf |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 set |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Envasado de madera |

| Tiempo de entrega: | 45 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| Nombre del producto: | Línea de la máquina de secado de gas | La transmisión es limitada de ancho: | 920 mm |

|---|---|---|---|

| Velocidad de la línea de producción: | 1-20m/min | Energía eléctrica: | 35.5kw |

| Tamaño de la máquina: | 90000 mm*1650 mm*2250 mm | Ciclo de producción: | 35-45 días |

| Condición: | Nuevo | Garantía: | 1 año |

| Resaltar: | gas-fired wood panel drying tunnel,high-temperature MDF curing oven,industrial particle board finishing oven |

||

Descripción de producto

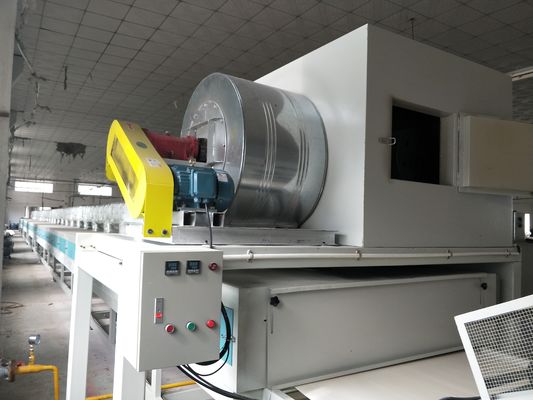

High-Temperature Gas-Fired Drying Machine for Wood Panel Coating Heating

-

Product Description:

This heavy-duty gas-fired drying machienne is designed for the rapid heating of coatings on wood-based panels like MDF, particle board, and HDF. It provides the high temperatures and intense air movement required to quickly cross-link, water-based, and solvent-based coatings, resulting in a durable, scratch-resistant finish. The direct-fired system offers maximum thermal efficiency for demanding factory environments.

-

Technical Parameters:

| Parameter Category | Details & Specifications |

|---|---|

| Model | OSM-TRQ-920 |

| Suitable Product | MDF, Particle Board, HDF, Plywood Panels |

| Heat Source | Direct Gas-Fired Air Make-up System |

| Max. Operating Temp | 250°C |

| Conveyor Width | 2200 mm (Customizable) |

| Panel Thickness | 3mm - 50mm |

| Energy Recovery | Optional Air-to-Air Heat Exchanger |

| Control System | PID temperature control with data logging |

-

Application:

Curing painted or coated furniture panels, cabinet doors, laminate flooring, and other engineered wood products.

-

Customization:

The tunnel is highly customizable. Options include different conveyor systems (chain, roller, flat-top), varying heat recovery systems to improve efficiency, and custom lengths to achieve the required cure time at your line speed.

-

Feature:

-

Fast Curing Times: High air temperature and velocity drastically reduce curing time.

-

High Efficiency: Direct-fired system puts 100% of the heat into the oven.

-

Robust Construction: Built to withstand harsh industrial conditions.

-

Enhanced Safety: Integrated flame supervision and fire suppression systems.

-

-

Support and Services:

Commissioning by certified engineers, compliance documentation for safety systems, and preventative maintenance contracts.

-

Packing and Shipping:

Major structural sections are pre-assembled. Internal components like burners and fans are packed securely within the sections to minimize site work.

-

FAQ:

Q: Is a direct-fired system safe for curing coatings?

A: Yes, when designed correctly. Our systems use 100% fresh air make-up, and the combustion gases are thoroughly mixed and diluted to safe levels before contacting the product. This is a standard and efficient method for industrial curing ovens.