Secado de gas natural rentable para la producción mejorada de tableros de silicato de calcio

Datos del producto:

| Lugar de origen: | PORCELANA |

| Nombre de la marca: | OSMANUV |

| Certificación: | ISO9001 |

| Número de modelo: | Se aplican las siguientes medidas: |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 set |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | Envasado de madera |

| Tiempo de entrega: | 35 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | Negociación |

|

Información detallada |

|||

| Nombre del producto: | Secadora de gas natural de 28 metros. | Dimensión (L*W*H): | Tamaño personalizado, 28000 mm * 2400 mm * 3140 mm |

|---|---|---|---|

| Fuerza: | 24 kw | Voltaje: | 380V/50Hz |

| Ancho de recubrimiento: | 1320m m | Velocidad de recubrimiento: | ajustable, 0,5-8 m/min |

| Garantía: | 1 año | Condición: | Nuevo |

| Resaltar: | Máquina de secado de gas natural,secador industrial de tableros de silicato de calcio,equipos de secado de gas rentables |

||

Descripción de producto

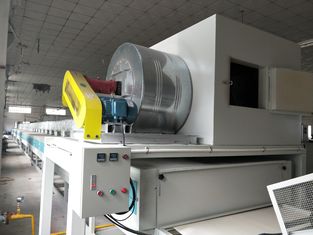

Secado de gas natural rentable para la producción mejorada de tableros de silicato de calcio

Descripción del producto

Esta línea de secado de gas natural está diseñada específicamente para tableros de silicato de calcio, proporcionando una distribución uniforme del calor y un control preciso de la temperatura durante todo el proceso de secado. El sistema asegura una eliminación óptima de la humedad, manteniendo la integridad y la estabilidad dimensional del tablero.

Parámetros técnicos

| Parámetro | Especificación |

|---|---|

| Modelo |

OSM-LRHG-1320T |

| Fuente de calentamiento | Sistema de quemador de gas natural |

| Temperatura máxima | 300°C |

| Ancho del transportador | 1320 mm (Personalizable) |

| Zonas de secado | 6 zonas (Personalizable) |

| Consumo de combustible | 15-25 m³/h |

| Sistema de control | PLC + Pantalla táctil HMI |

Aplicación

Secado y curado de tableros de silicato de calcio, paneles ignífugos y materiales para techos arquitectónicos.

Personalización

-

Personalizable configuración de la zona de secado

-

Personalizable velocidad y ancho del transportador

-

Personalizable perfilado de temperatura

Característica

-

Distribución uniforme del calor

-

Control preciso de la temperatura

-

Operación energéticamente eficiente

-

Construcción robusta

Soporte y servicios

-

Supervisión de la instalación

-

Programa de capacitación para operadores

-

Garantía de 12 meses

-

Soporte técnico

Embalaje y envío

-

Caja de madera resistente

-

Embalaje a prueba de intemperie

-

Estándares de exportación profesionales

Preguntas frecuentes

P: ¿Cuál es la tasa de consumo de energía?

R: El consumo promedio es de 18-22 m³/h, dependiendo de los requisitos de producción.